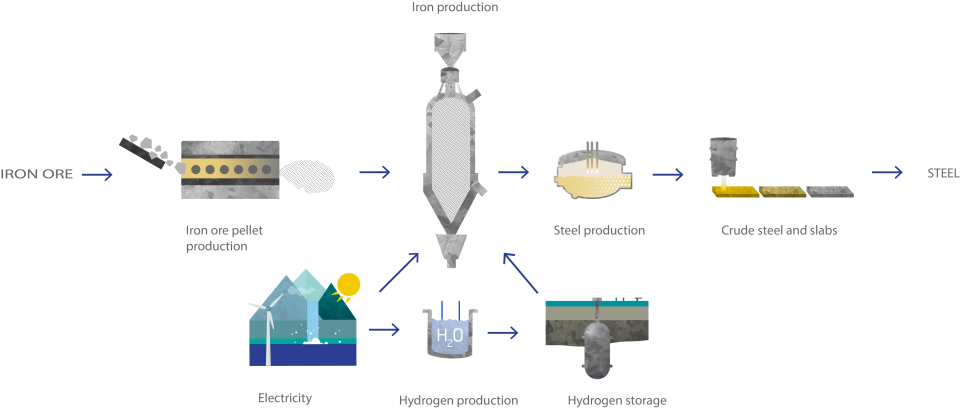

SSAB, LKAB and Vattenfall are making a unique joint effort to change the Swedish iron and steel industry fundamentally. Under the name HYBRIT, we are working together to develop the first fossil-free steel.

The HYBRIT technology has the potential to reduce Sweden’s total carbon dioxide emissions by at least ten percent. This is equivalent to one third of the emissions from the industry and may, in the future, help to reduce emissions from iron and steel production globally.

HYBRIT’s mission

14 December 2023

The HYBRIT initiative receives support from Industriklivet, the Swedish Energy Agency’s program to support Swedish industry’s transition to fossil-free.

1 November 2023

LKAB and Hybrit Development AB have submitted a supplementary application to the Swedish Energy Agency for support for the next step in the development of the HYBRIT initiative. The supplement clarifies that LKAB is responsible for the construction of the planned demonstration plant and will be the main recipient of any state aid. At the …

12 October 2022

New research within the HYBRIT project, driven by SSAB, LKAB and Vattenfall, shows superior results on the properties and quality of the hydrogen direct reduced sponge iron (H-DRI) made using HYBRIT technology.

23 September 2022

SSAB, LKAB and Vattenfall’s HYBRIT pilot facility for the storage of fossil-free hydrogen gas is now in operation in Luleå. The rock cavern storage facility is the first of its kind in the world for storing fossil-free hydrogen gas.